News Detail

Characteristics and application fields of non-woven fabric rollers

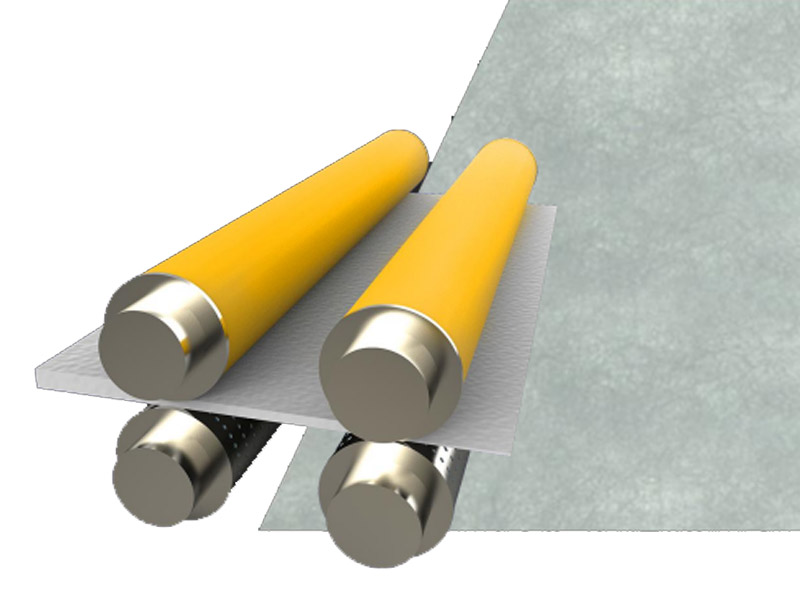

Characteristics of non-woven fabric rollers

1. The non-woven fabric roller is a roller shaft used in the post-processing of non-woven fabrics. The diameter of the non-woven roller is approximately 300 millimeters. The inner part of the roller is an iron core. The sheet-like non-woven fabric is wrapped around the outer part of the non-woven fabric roller, pushed and pressed with force, and then placed on a lathe for polishing before the finished product is formed.

2. Nowadays, only 1-2 people are needed to supervise the operation of non-woven rolls, adjust the production speed and product size within a certain range, and achieve multi-functional fully automated office. In addition, non-woven rolls can further achieve environmental office effects and have the function of recycling waste materials during the production process, automatically collecting the remaining waste materials from bag making, which helps with the secondary utilization of fabrics.

Applicable industries for non-woven fabric rollers

1. Printing and dyeing industry: calendering processing of pure cotton, polyester cotton, silk fabrics, synthetic fibers, linen, woolen textiles, and their blends.

2. Leather industry: Rolling processing of artificial leather and other materials.

3. Plastic industry: Various plastics such as PVC, ABA, PP, PT, PC, etc.

4. Paper industry: surface rolling processing of various types of paper.

5. Metallurgical industry: Rolling and pressing processing of various non-ferrous metals.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!