Product Detail

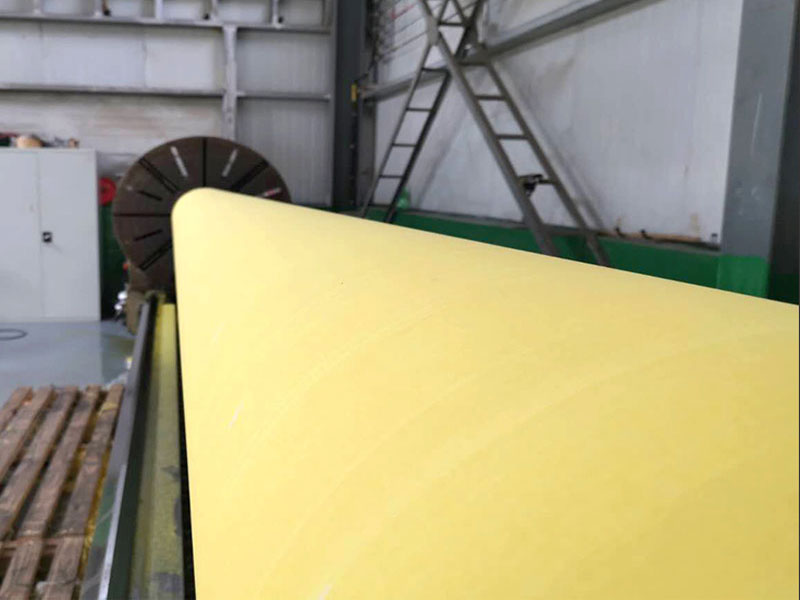

Non-woven Mill Roll - Car Application

Introduction of materials of each brand

Japanese materials characteristics: Ultra-fine fiber materials are used, which have high requirements for the adsorbed liquid medium. Under complex working conditions, fiber detachment is likely to occur. The arrangement and combination is a hierarchical cross-form with good resilience.

American ** brands materials characteristics: Mainly uses DuPont nylon medium-coarse fiber, its main characteristics are good air permeability, good adsorption of liquid media, and a relatively wide range of media requirements; it is mainly arranged crosswise in the horizontal and vertical directions, has good tear resistance, and has a certain degree of resilience.

Taiwan HDE materials characteristics : DuPont nylon crude fiber is used. Its main characteristics are good water permeability and air permeability. Generally, it does not have high requirements for liquid media. The arrangement and combination are irregular forms. The biggest advantage of this arrangement is that it can resist extrusion, stretching and tearing in any direction, and has good resilience.

Main parameters of HDE roller

| Temperature resistance | ≤200℃ |

| Normal length | 500-5500mm |

| Normal outer diameter | φ120-500mm |

| Hardness control | 55-100 shore A |

| PH value range | 2-10 |

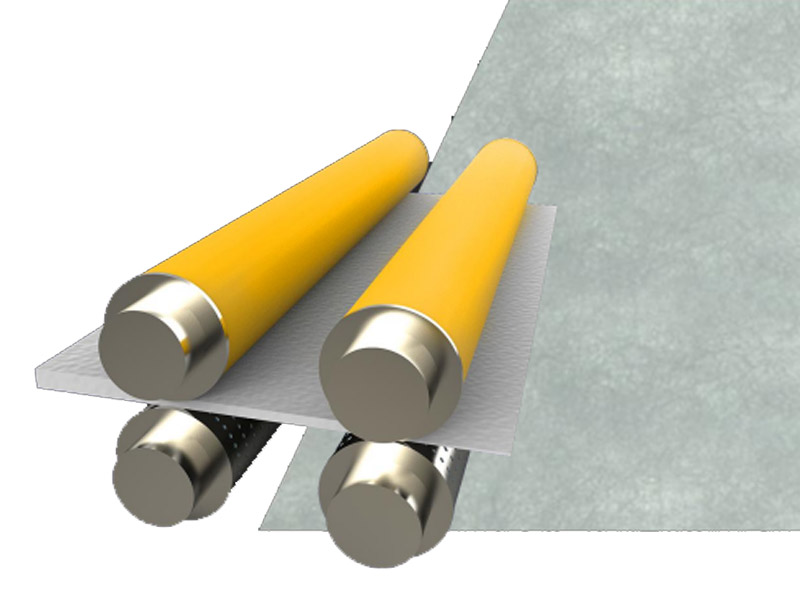

Line pressure and winding calculation

E: Young's modulus (elastic modulus) of steel (Kgf/cm3)

I: moment of inertia (cm4)

Solid shaft:

R=shaft radius (cm)

Tube axis:π/4*(R4-r4)

R=tube outer diameter (radius)

r=tube inner diameter (radius)

W: Line pressure (kgf/cm)

(2*P+roller weight)/roller surface length

Winding amount δ={(5*W*L4)/(24*E*I)}*(1+12/5*a/L)

Roller repair process

1. Old roller inspection

2. Confirmation of repair plan

3. Replacement of damaged parts

4. Turning and grinding of roller surface

5. Performance inspection

Application in the automotive industry

Oil film is controlled at 0.5-1.5g/㎡;

Applicable plate thickness is 0.5-3.0mm;

Feeding speed is 100-200m/min;

Pressure range is 0-150bar;

Roller surface hardness is adjustable from 90 to 98 degrees Shore A;

Surface roughness is ≤Ra4

Roller surface friction coefficient is 0.33-0.68

Diameter tolerance is 0-±0.3mm, and the measurement position is ≥10 points.

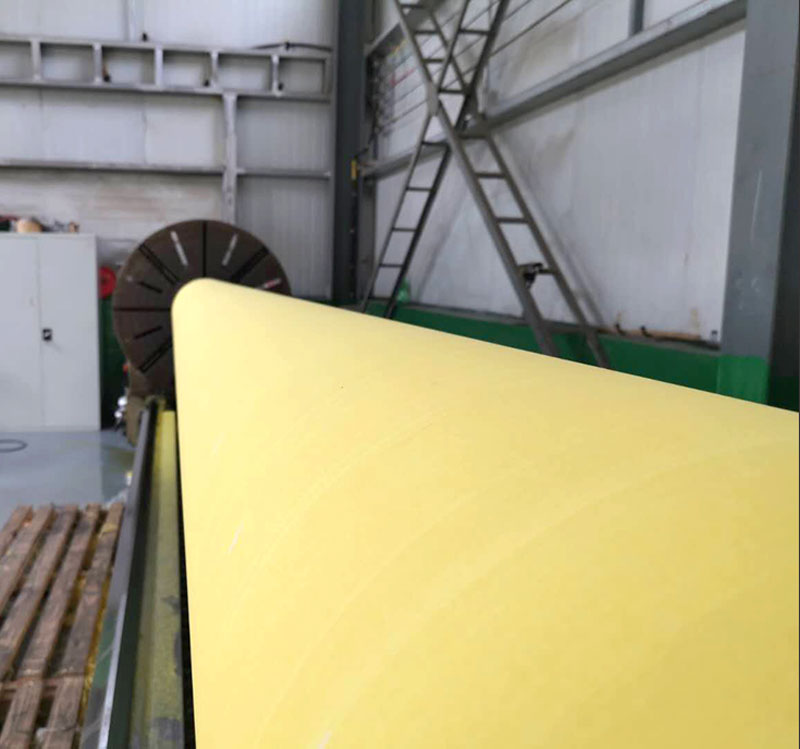

On-site introduction to the automotive industry

Product videos

Production and processing

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!