Product Detail

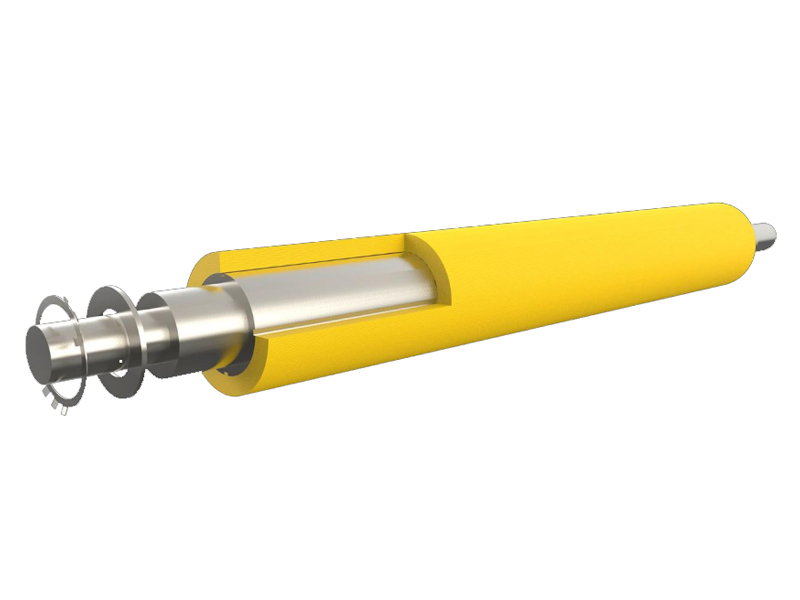

Non-woven Mill Roll - Metallurgical Application

Advantages of application in metallurgical industry

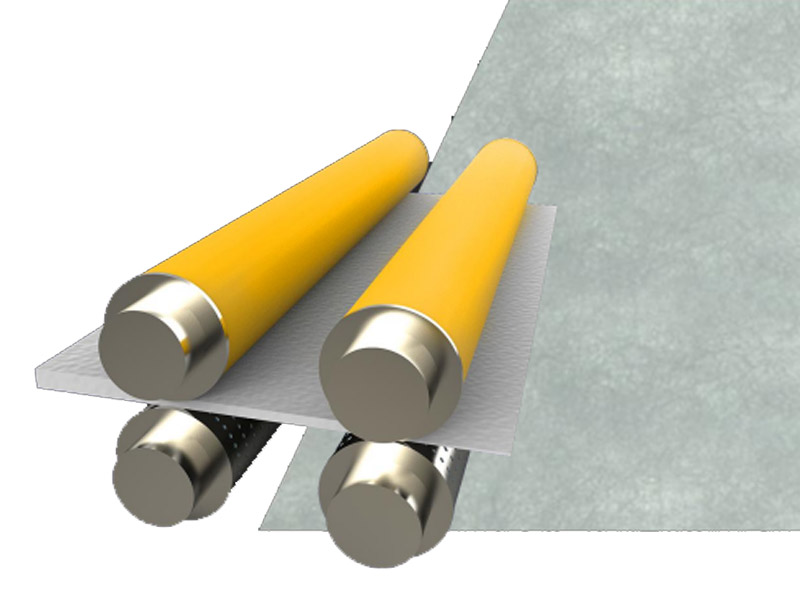

When producing plates of different widths, it completely solves the problem of wide and narrow printing of plates and improves the quality of plates and strips;

Greatly reduces the oil content of finished plates and strips, and greatly improves the surface cleanliness;

Reduces the cost of downtime for roller replacement, greatly reduces the time for transporting rollers and the space for storing rollers, and waste disposal;

Adopting inert roller assembly can save considerable energy consumption;

The non-woven roller has a high friction coefficient and can be used as a passive roller to ensure that it will not damage the steel strip while saving electricity.

Application in metallurgical industry

1. Stainless steel:

Precisely control oil film

Ultra-long service life

Self-repairing ability

Can be repeatedly polished

Solve the problem of wide and narrow printing

No slipping

Improve the squeezing effect

2. Carbon steel:

Ultra-long service life

Life span is dozens of times that of rubber rollers

Improve the surface quality of sheet metal

Solve the problem of wide and narrow printing

Improve the squeezing effect

Main parameters of HDE Roller

| Temperature resistance | ≤180℃ |

| Normal length | ≤5500mm |

| Normal outer diameter | ≤650mm |

| Hardness control | 55-100 shore A |

| PH value range | 2-10 |

Line pressure and winding calculation

E: Young's modulus (elastic modulus) of steel (Kgf/cm3)

I: moment of inertia (cm4)

Solid shaft:

R=shaft radius (cm)

Tube axis:π/4*(R4-r4)

R=tube outer diameter (radius)

r=tube inner diameter (radius)

W: Line pressure (kgf/cm)

(2*P+roller weight)/roller surface length

Winding amount δ={(5*W*L4)/(24*E*I)}*(1+12/5*a/L)

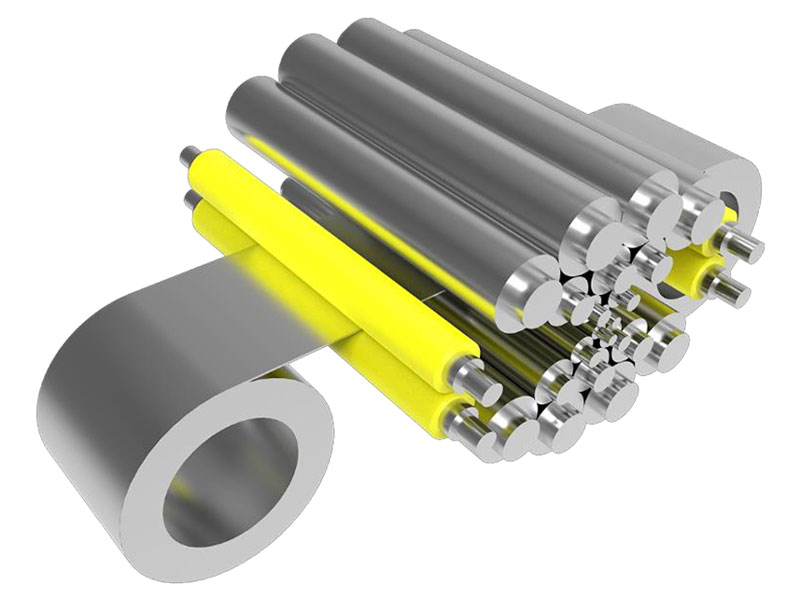

Work Display

Production and processing

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!