Product Detail

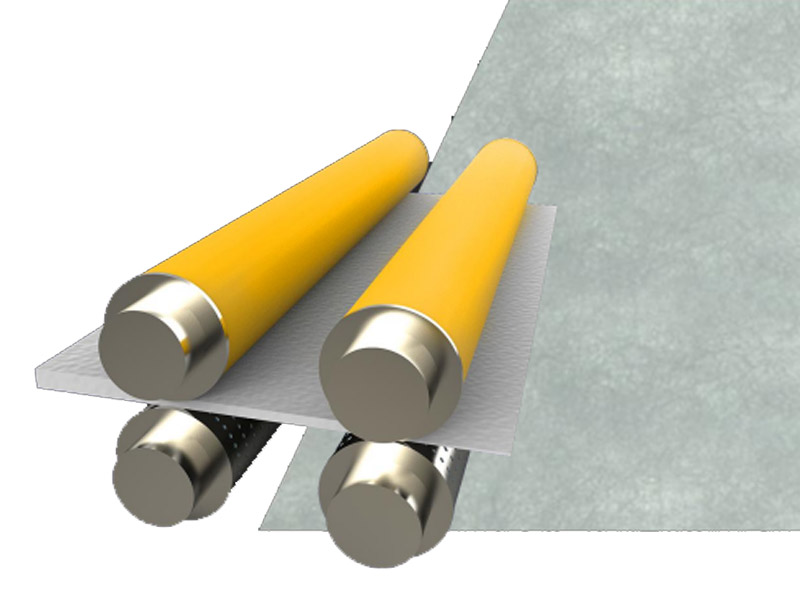

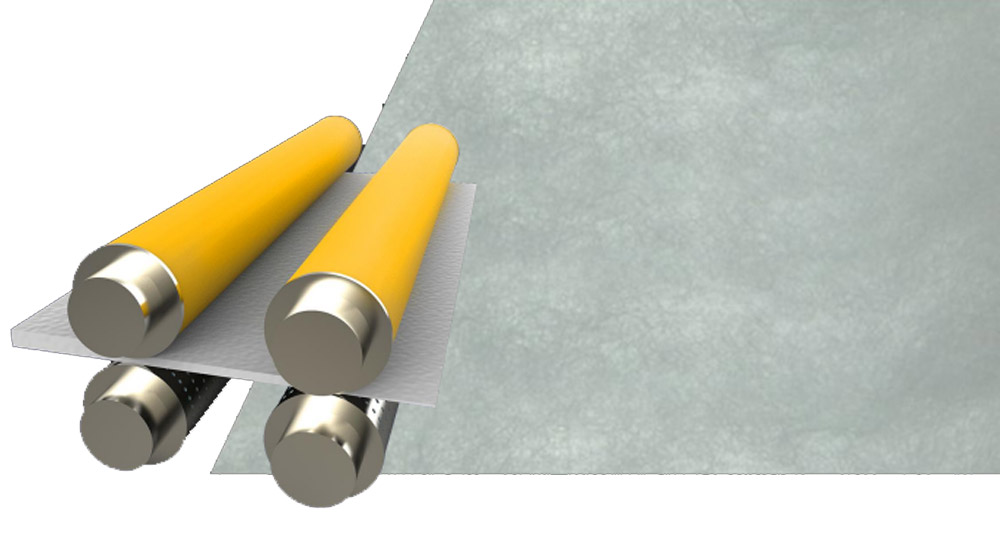

Non-woven Mill Roll - Viscose Fiber Application

Viscose Industry Industry Features

Can withstand higher downforce

Can achieve greater hardness and is not easy to shrink.

Acid and alkali resistant, not easy to age, no falling off or deformation after long-term use.

Higher drainage.

For single-point force, it has good resilience. (Mainly for on-site braided wire).

No fading, no fading in long-term use.

Longer service life

Viscose industry Industry Application

1. Significantly reduce the rolling rate

2. Improve work efficiency

3. Energy saving of more than 10%

4. Ultra-long service life

5. No shrinkage and aging

Line pressure and winding calculation

E: Young's modulus (elastic modulus) of steel (Kgf/cm3)

I: moment of inertia (cm4)

Solid shaft:

R=shaft radius (cm)

Tube axis:π/4*(R4-r4)

R=tube outer diameter (radius)

r=tube inner diameter (radius)

W: Line pressure (kgf/cm)

(2*P+roller weight)/roller surface length

Winding amount δ={(5*W*L4)/(24*E*I)}*(1+12/5*a/L)

Main parameters of HDE Roller

| Temperature resistance | ≤190℃ |

| Normal length | 6000mm |

| Normal outer diameter | φ700mm |

| Hardness control | 55-100 shore A |

| PH value range | 2-10 |

Work Display

Product videos

Production and processing

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!