News Detail

Production process flow of non-woven fiber rollers

The hot rolling manufacturing process of non-woven fabrics

1. Raw material preparation:

The manufacturing of non-woven fabrics mainly uses polymer fibers as raw materials. Before hot rolling manufacturing, it is necessary to preprocess the raw materials, such as heating, melting, and filtering.

2. Melting:

The pre treated raw materials are transported to the melting chamber of the hot rolling mill, and the raw materials are completely melted by the action of high temperature and pressure. During the melting process, it is necessary to control the temperature and pressure to ensure that the raw materials can fully melt.

3. Spinning:

Melted raw materials are stretched into fine fibers through a spinning mechanism, and a continuous fiber flow is formed through high-speed rotating nozzles. The fiber flow rapidly cools in the air and forms the basic structure of non-woven fabric.

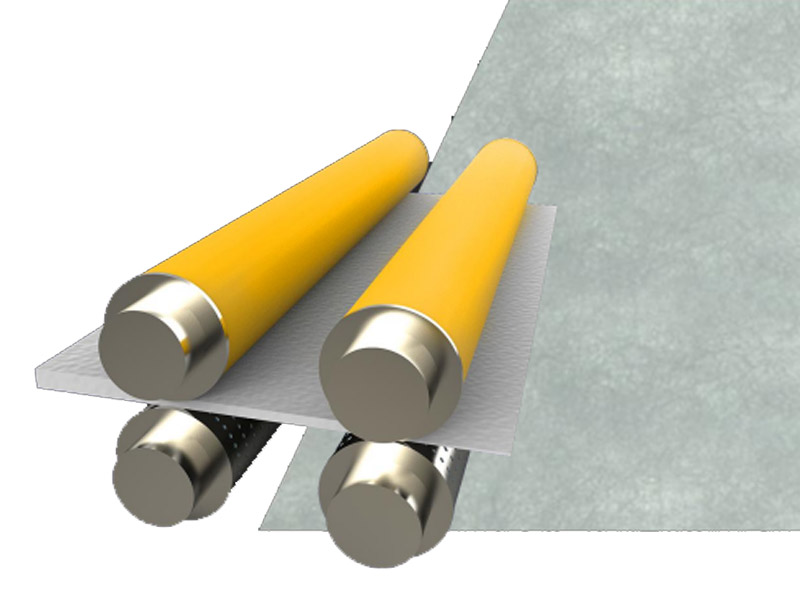

4. Hot rolling:

The non-woven fabric that has been spun enters the hot rolling machine, and through the action of the hot rolling roller and pressure roller, the fibers are more tightly bonded together. This step is mainly to improve the strength and wear resistance of non-woven fabrics.

5. Cooling:

After hot rolling, the non-woven fabric undergoes rapid cooling through a cooling device. During this process, the structure of the non-woven fabric becomes more stable and achieves the required softness and moisture absorption.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!