News Detail

The Effect of Domestic Replacement of Squeezing Roller for Beijing Houdele Automobile Cleaning Machine

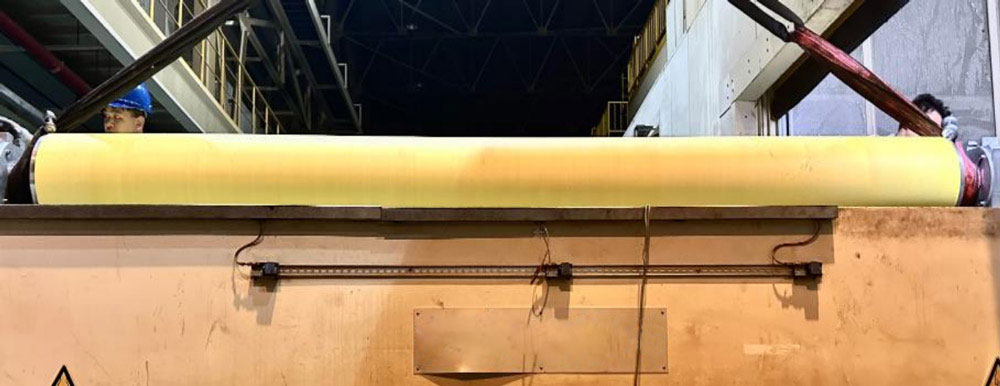

In 2023, we signed a contract with Wuhan Dongfeng Passenger Car for the localization transformation of the extrusion roller of the cleaning machine on Line 2 of the stamping workshop. In the absence of spare parts for use by Party A, we conducted on-site surveying and mapping of the SMT imported cleaning machine extrusion roller, drew attention to the installation dimensions of the roller core, bearing seat, etc., and arranged for independent production. The roller surface part was replaced by our own brand HDE non-woven fabric. The project was installed and debugged on September 13, 2023, and the first startup debugging was successful.

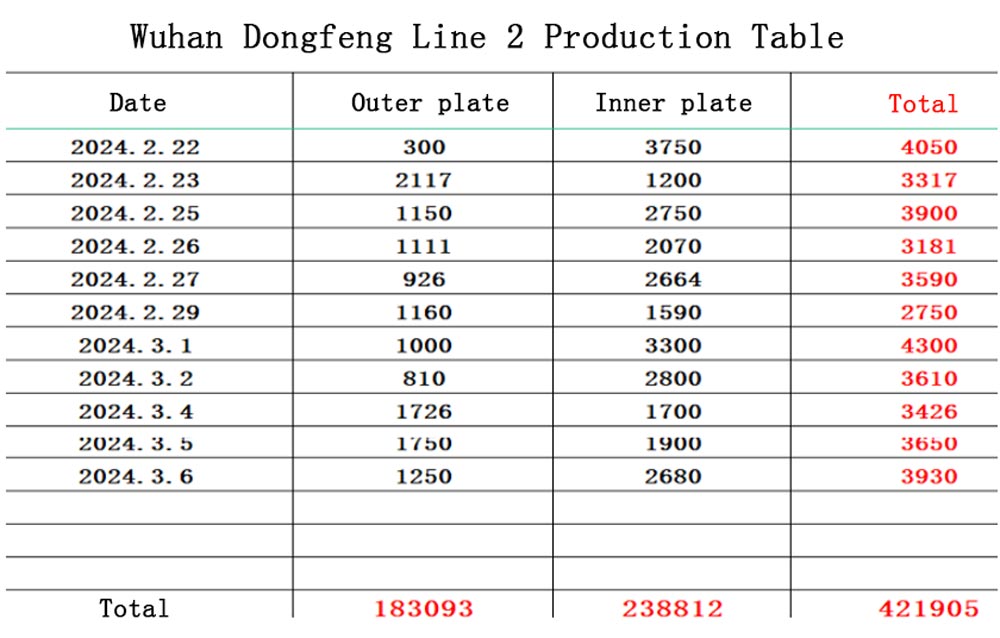

After the official production, we cooperated with Party A to track the entire production process and collect data. The main models produced in the workshop include Fengshen Haohan, Yixuan, AX7, Haoji, E70, etc. As of March 6, 24, we have produced more than 420000 stamped automotive panels and the equipment is running stably.

On March 7th, we cooperated with the production inspection personnel in the workshop and conducted online oil film testing on the effectiveness of the squeezing roller used in the past six months under the witness of third-party Changan Automobile professionals. The workshop's Line 2 is equipped with 2 pairs of non-woven fabric drying rollers. In this renovation, the mid-term pair has been replaced and installed at the outlet end to be used in conjunction with the old rollers. Cleaning oil and fuel injection quantity:

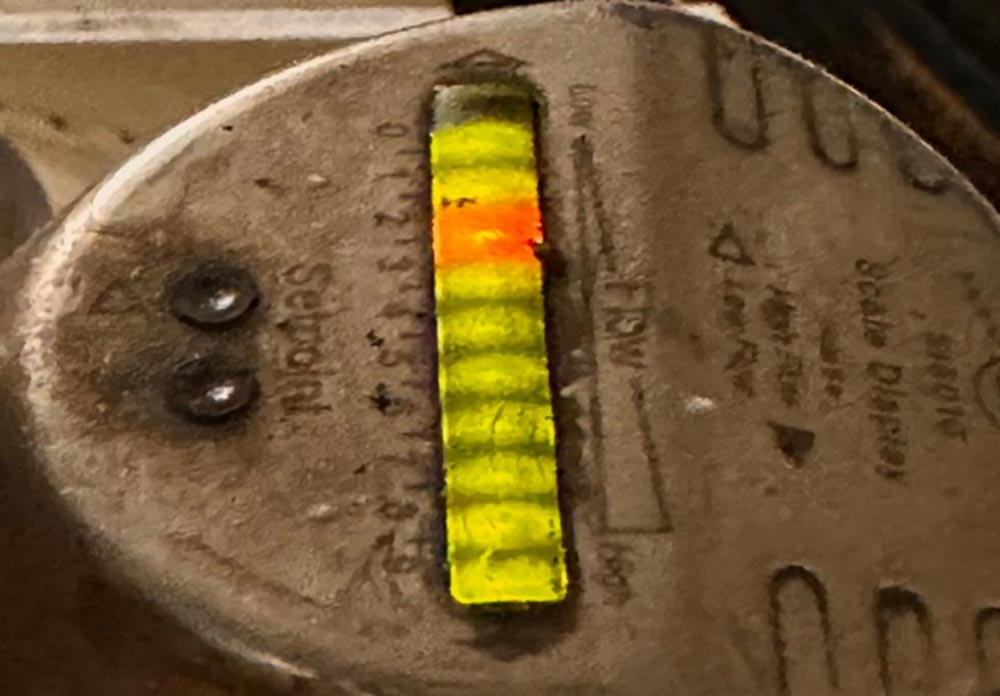

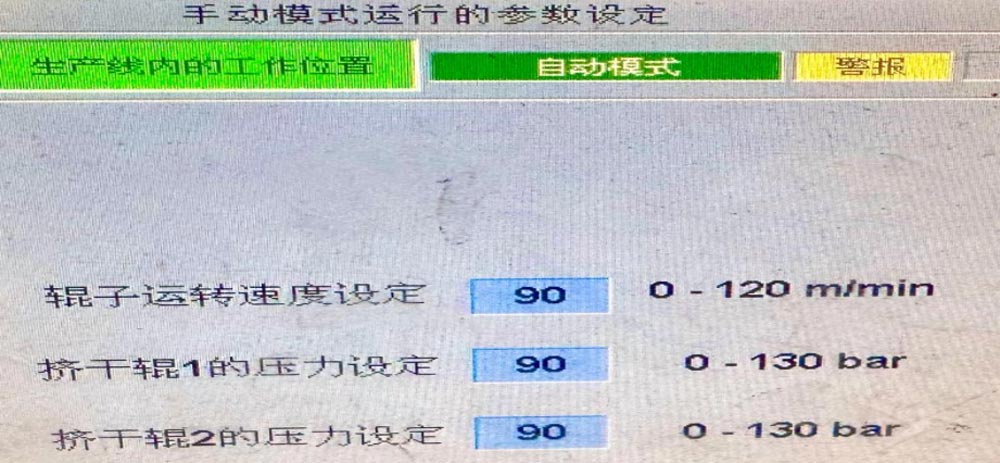

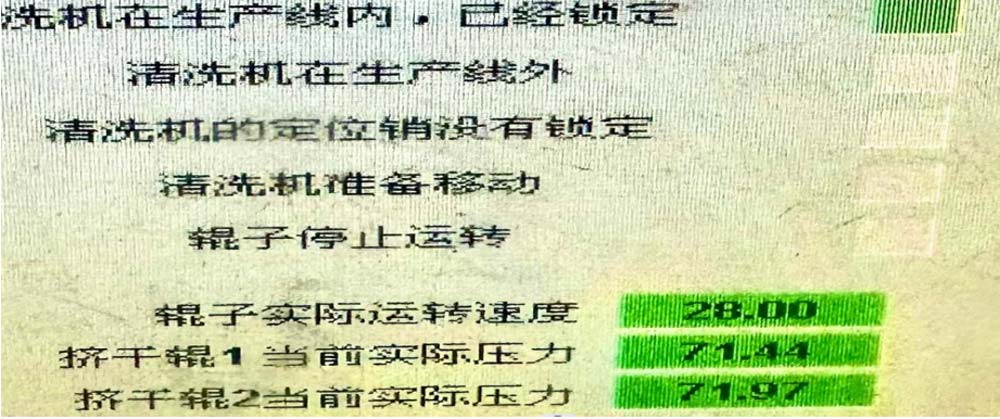

The production line cleaning machine has set production line parameters with a speed of 90m/min and a pressure of 90bar. The actual operating parameters have a speed of 28m/min and a pressure of 71.97bar. The photo reference is as follows:

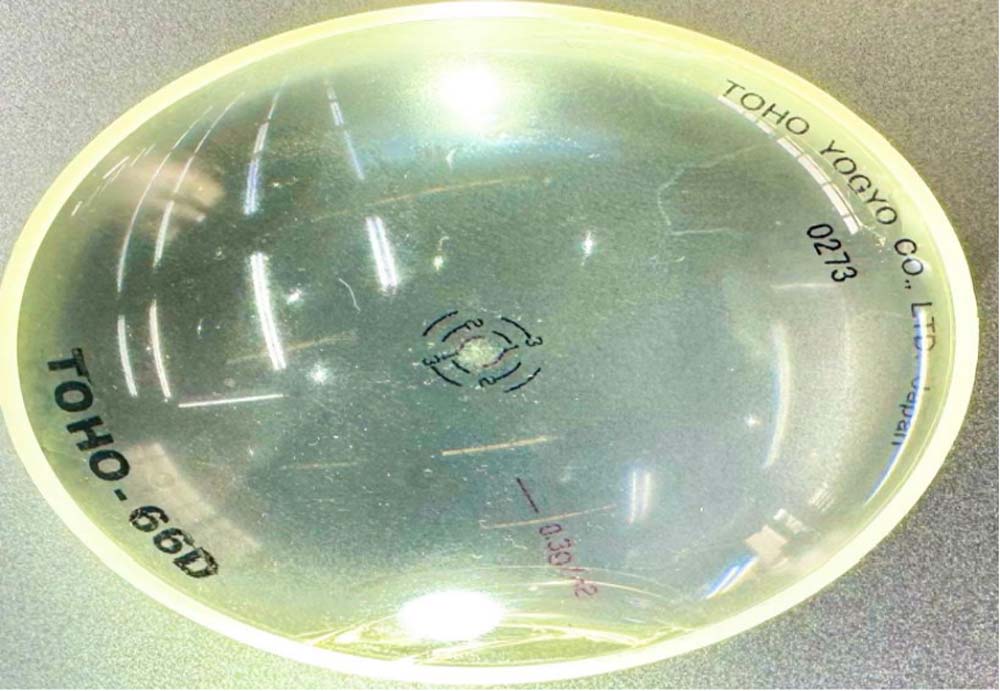

The oil film thickness gauge imported from Japan was used by both parties this time. The online inspection of the stamped parts includes the stamped parts of the rear and front cover outer plates of the cleaning machine, as well as the stamped parts of the hood inner plate. There is a slight flicker of oil on the outlet plate surface of the cleaning machine, and there is a small amount of oil strip and oil storage at 10-15mm of the edges and hole edges (generally, oil storage at 15-20mm of the edges is not within the detection range). The oil film gauge displays within 0.8 grams;

Observing the surface of the stamped part as a whole, there are no oil bands or obvious oil marks, and there is no oil band phenomenon at the edges. The oil film is detected to be within the range of 0.5-0.8 grams;

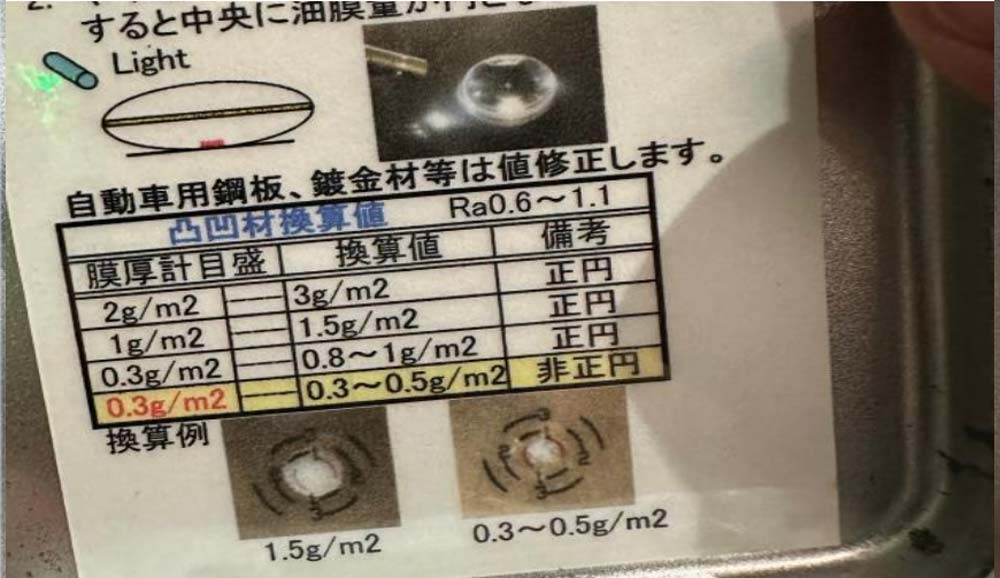

Reference value for oil film analyzer:

Through this tracking test, after half a year of practical testing and 420000 plates, the extrusion drying roller of the Houdele HDE brand has not shown any scratches or obvious width and narrow marks on the roller surface, meeting the technical agreement requirements of both parties. The use effect on the SMT cleaning machine is not ideal. In the future, we will conduct further tracking and testing at the node of 1 million plates within a year to verify the effectiveness of use, and once again prove that the application effect of the HDE domestic brand extrusion drying roller in automotive cleaning lines can be compared to imported brands in Europe, the United States, and Japan.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!