Product Detail

Tower Top Roller Cloth - Cold Rolled Galvanizing

I. Product Introduction

Our company has successfully developed the galvanizing line top roller cloth-PT1100 after long-term exploration and testing by using mature and advanced foreign technology. The new high-tech special fiber used in this product has excellent properties such as ultra-high strength, high modulus, acid and alkali resistance, flame retardancy, and high temperature resistance. It is an important national defense military material and is widely used in military, aviation, aerospace, electromechanical, construction, and automobiles. The top roller cloth is also used because of its excellent properties. After using this product on the galvanized sheet production line, it can not only avoid the bright spots and impurity marks on the inside of the galvanized sheet, improve product quality, but also reduce the wear of the top roller and extend the service life of the top roller.

II. Advantages

1. Avoid top roller indentation

Because the surface of the cloth is dense and smooth, has no melting point, does not generate static electricity, has no adhesion to metals such as lead and zinc, even small zinc slag will fall off, preventing the top roller from embossing defects and improving the quality of galvanized sheets.

2. Eliminate physical bright spots

Using a smooth top roller wrap with very low thermal conductivity can eliminate physical bright spots and improve the surface quality of galvanized sheets.

3. Environmental protection and safety

Because the wrap is made of high-temperature resistant special materials, it has extremely strong thermal stability and will not produce harmful gases and waste in the production of galvanized sheets.

4. Simple installation

The company only needs to slightly modify the existing equipment and prepare some simple accessories to install and use it.

5. Easy replacement

There is no need to disassemble the top roller. It can be replaced during each stop time, and each roller takes about 60-90 minutes.

6. Professional value

The wrap does not require maintenance during use, with low one-time investment, and uses low cost to improve product quality and corporate image, winning unlimited value space.

Ⅲ. Parameters

| Product Specifications | PT1100 |

| Main material | 100% ARIMID |

| Accessory material | ARIMID, NYLON, PP |

| Base weight | 200g/㎡ |

| Base thickness | 0.62mm |

| Dimension tolerance Length | Top roller circumference + 150mm±10mm |

| Width | Top roller length + 200mm±30mm |

| Using temperature | <350℃ |

| Instantaneous temperature | 500℃ |

| Thermal conductivity | 0.17W/m.K |

| The above data are test values rather than guaranteed values. The specific size is designed according to the top roller size | |

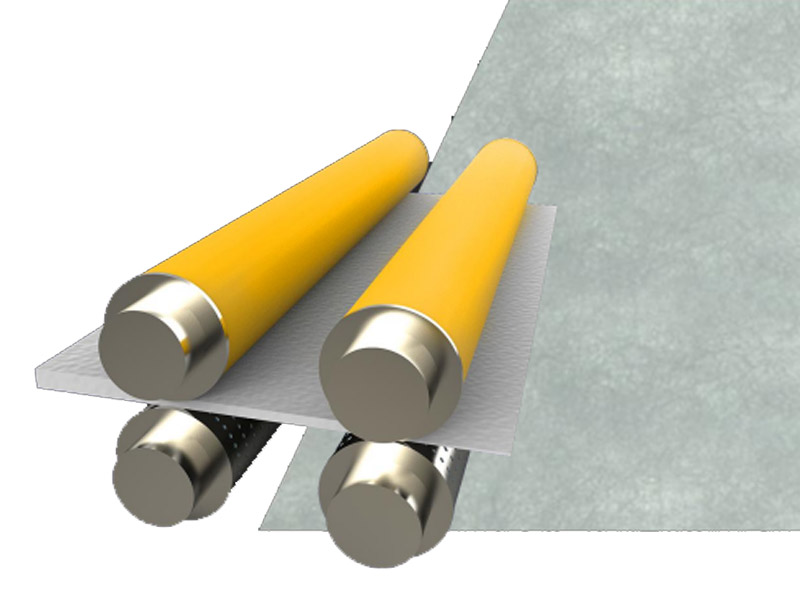

Ⅳ. Installation of wrapping cloth

Through manual sewing techniques, at least 8 seams are made at the connection of the tower top roller cover to avoid shelf marks and cracks during use.

Steel bars are passed through both sides of the wrapping cloth, and are hung with basket bolts and welded hooks to tighten the wrapping cloth. At the same time, steel bars are passed through the basket bolts to prevent them from loosening.

Production and processing

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!